Treatment Process

The untreated (raw) water from Lake Cochichewick flows by gravity from the intake structure in the lake directly into the Low Lift Pump Station. The water passes through a traveling water screen, which removes any floating debris, and into the wetwell. The water is pumped from the wetwell to the ozone contact chamber. Ozone gas is generated on-site, and is used as a strong oxidant and disinfectant, breaking down organic matter making the water easier to filter.

The untreated (raw) water from Lake Cochichewick flows by gravity from the intake structure in the lake directly into the Low Lift Pump Station. The water passes through a traveling water screen, which removes any floating debris, and into the wetwell. The water is pumped from the wetwell to the ozone contact chamber. Ozone gas is generated on-site, and is used as a strong oxidant and disinfectant, breaking down organic matter making the water easier to filter.

From the ozone contact tank the water enters the plant's two double stage rapid mix basins.The coagulant, poly-aluminum chloride is added at this stage in the process to assist in the removal of impurities from the water. Mechanical mixers uniformly distribute the chemicals throughout the raw water. This processes known as coagulation and flocculation and is essential to make small particles stick together so that they become large enough to settle out during the next process in treatment called sedimentation.

The flocculated water enters the four sedimentation basins where the solids settle to the bottom, forming a thin layer of solid particles. The settled solids are periodically removed from the bottom of each basin by a moving siphon and transferred by gravity to a storage tank. The siphon system contains no moving parts in the water, and therefore does not agitate the solids, providing for a more effective and efficient means of the solids removal.

The water that is now clearer of the removed particles then flows into the carbon filters. North Andover has eight deep bed dual granular activated carbon (GAC) and sand filters. These filters remove any remaining impurities. The filtered or "finished" water is then sent to the clearwell which holds 620,000 gallons and is located under the plant. To complete purification, sodium hypochlorite is added for disinfection to the filter effluent. Sodium Hydroxide is also added for pH control adjustment. Fluoride is added to the finished water at about 1ppm to prevent tooth decay and cavities. As a final step, Zinc Orthophosphate, a corrosion inhibitor, is added as the water leaves the plant to protect the linings of the distribution system pipes. From there, treated water is pumped into North Andover's water distribution system. The plant is equipped with four finish water pumps, with a pumping capacity of 12 million gallons per day.

The water that is now clearer of the removed particles then flows into the carbon filters. North Andover has eight deep bed dual granular activated carbon (GAC) and sand filters. These filters remove any remaining impurities. The filtered or "finished" water is then sent to the clearwell which holds 620,000 gallons and is located under the plant. To complete purification, sodium hypochlorite is added for disinfection to the filter effluent. Sodium Hydroxide is also added for pH control adjustment. Fluoride is added to the finished water at about 1ppm to prevent tooth decay and cavities. As a final step, Zinc Orthophosphate, a corrosion inhibitor, is added as the water leaves the plant to protect the linings of the distribution system pipes. From there, treated water is pumped into North Andover's water distribution system. The plant is equipped with four finish water pumps, with a pumping capacity of 12 million gallons per day.

At that point when water leaves the treatment plant, it is safe, odorless, colorless and tasteless. The water is then pumped through the distribution system to two sanitized 2.2 million gallon in-ground storage tanks and into a one million gallon stand pipe and into your homes and businesses.

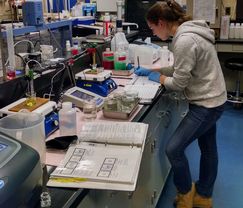

To ensure you that we are providing the highest quality of water available, your water system is operated by Massachusetts certified operators who oversee the routine operations of our system. The water quality is constantly monitored by us, in our on-site laboratory, and by the MassDEP to determine effectiveness of existing water treatment and to determine if any addition treatment is required.